Maintaining optimal pressure levels in a chiller system is critical for ensuring efficient and reliable operation. When pressure is too high or too low, it can lead to performance issues, energy waste, and even costly equipment damage.

Real-time pressure monitoring using a Pressure Transducer provides the insights needed to keep your system running smoothly. By continuously tracking pressure data, you can catch early warning signs of problems like pump malfunctions, system imbalances, or refrigerant leaks—before they escalate into major issues.

What is a Pressure Transducer?

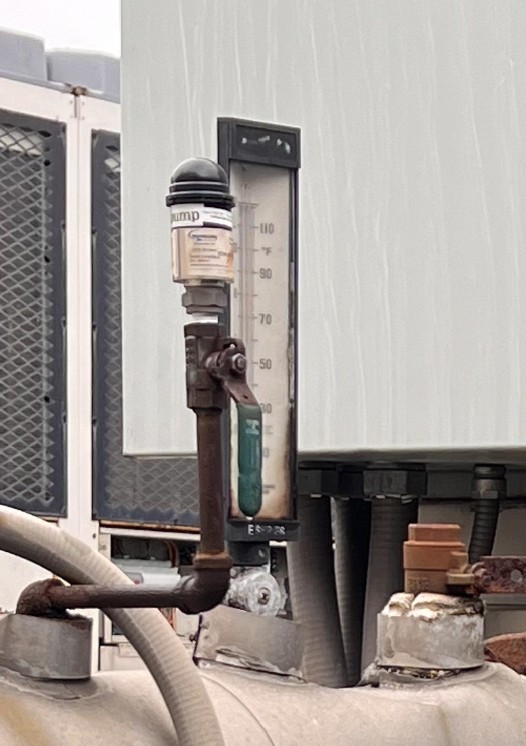

A pressure transducer is a sensor that responds to the pressure of a fluid such as water, air, or refrigerant and converts it into an electrical signal that can be measured, recorded, or monitored in real time.

In Chiller systems a pressure transducer can help you monitor chilled water pressure (supply and return), detect pump issues and verify pressure during equipment startups.

Source : Hydracheck

Source: CUNY BPL

Why Facilities Managers should use pressure transducers:

- Track: Monitor chilled water supply and return pressures.

- Detect: Abnormal system behavior, such as failing pumps.

- Verify: Get real-time pressure conditions during startup under different load scenarios.

Benefits of Using a pressure transducer:

- Real time monitoring: Getting continuous pressure readings helps you catch any early issues before they get worst or become unrepairable.

- System Efficiency: Maintaining the proper pressure at all times, reduces energy consumption and extends the lifespan of the pumps.

- Fault detection: Detect pump malfunctions, or leaks in the system.

You can check out our equipment library to find a Pressure Transducer suitable for your application by using the various filters and search functionality. For more guidance on equipment suitable depending on the application, see our measurement guides.