As warmer weather approaches, it’s essential to get ahead of potential cooling issues by proactively preparing your cooling systems. A proper start-up procedures ensure chillers, cooling towers, and RTUs are functioning within design parameters, minimizing the risk of system failures and unplanned downtime during peak demand, also keeps your facility comfortable all summer long.

What is a Ultrasonic Flow Meter?

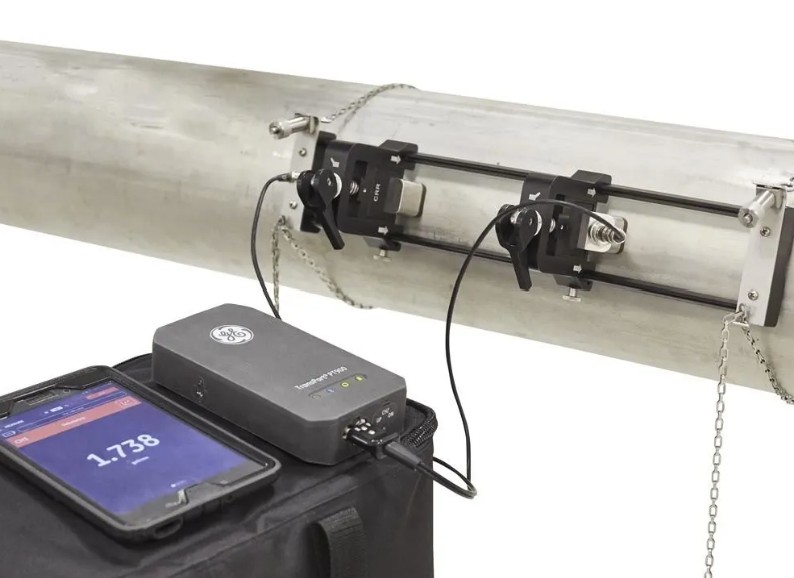

An ultrasonic flow meter is a tool that helps you measure how much water is moving through your pipes—without cutting into them. It uses sound waves to check flow rates quickly and accurately, making it a safe and efficient way to monitor systems like chillers and cooling units, especially during seasonal start-ups.

Its non-invasive technology enables building maintenance teams to perform key diagnostics—such as measuring chilled water flow through air handling units, detecting and correcting overflow, and readjusting or balancing valves to ensure proper water flow rates.

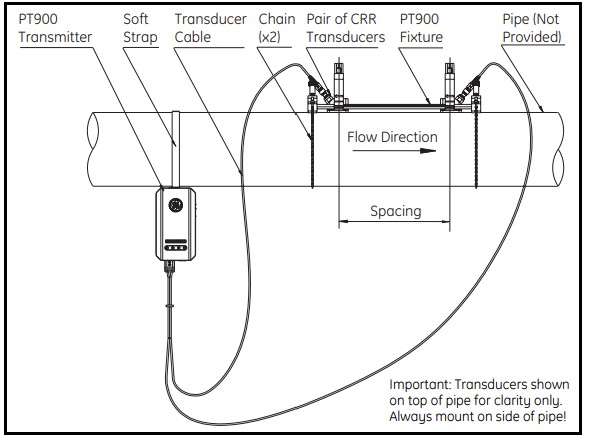

PT900 Quick Start Guide

Benefits of Using an Ultrasonic flow meter for chillers, cooling towers and RTU’s

- Suitable for variable flow rates: Good for modulating systems, it can accurately measure flow with pumps that operate with variable frequency drive systems in chillers and cooling towers.

- Energy Efficiency Monitoring: Most modern ultrasonic flow meters are equipped with temperature sensors, enabling the measurement of both supply and return water temperatures—key data points used to calculate the energy consumption (BTUs) of HVAC equipment.

- Predictive Maintenance: Identifying leaks, detect flow irregularities in chiller and cooling tower loops such as reduced flow due to blockage, or unexpected increases that may indicate a leak.

You can check out our equipment library to find a ultrasonic flow meter suitable for your application by using the various filters and search functionality. For more guidance on equipment suitable depending on the application, see our measurement guides.