Building Re-tuning (BRT), as developed, documented and implemented in many buildings by the Pacific Northwest National Laboratory (PNNL), is an effective set of low- and no-cost measures capable of reducing building energy consumption.

The effective use of BRT requires a building automation system (BAS) that meets minimum requirements, namely one that has:

- Been properly configured and commissioned;

- A prerequisite degree of connectivity to building system sensors; and

- The ability to capture and store building system parameter values measured at regular intervals for an appreciable period, such as two weeks or longer.

However, the significant majority of today’s medium (25,000-50,000 sf) and large commercial/ institutional buildings (>50,000 sf) do not have a BAS that meets these standards, or may not have a BAS at all. To address this segment of buildings, the CUNY Building Performance Lab (BPL) has developed a set of BRT-like measures that use readily-available data loggers and sensors in lieu of a BAS. These instruments are included in defined kits for each measure, along with a notebook computer and/or tablet and associated data management software. The intent is for these measures to be sufficiently accessible and easily reproducible, so that they may be implemented by a broad audience of facility personnel.

CUNY BPL’s solution is referred to as the “noBAS BRT” protocol, and its measures are described in this user guide. Also included are step-by-step instructions to assemble the kits, initialize and install the field equipment, and extract and visualize resulting building system data. Finally, the diagnosis of certain conditions and suggested actions for more efficient building operations are offered for each measure.

Below is a summary of each measure’s guide:

Fan Schedule

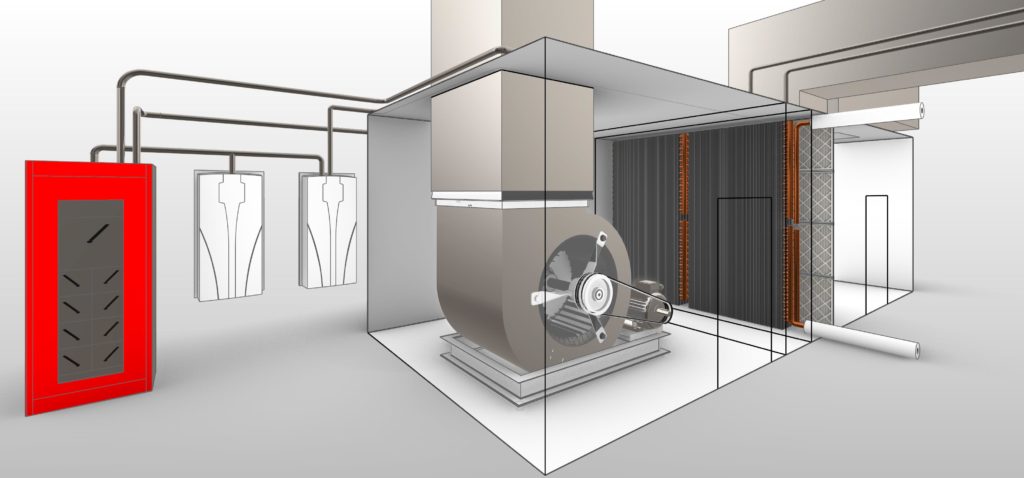

The supply fan status in an air handling unit (AHU) or roof top unit (RTU) is monitored to confirm that the fan(s) is OFF when it should not be operating and ON when it should be on.

This measure applies to fans that are not controlled by a variable frequency drive (VFD), or sometimes called variable speed drive (VSD).

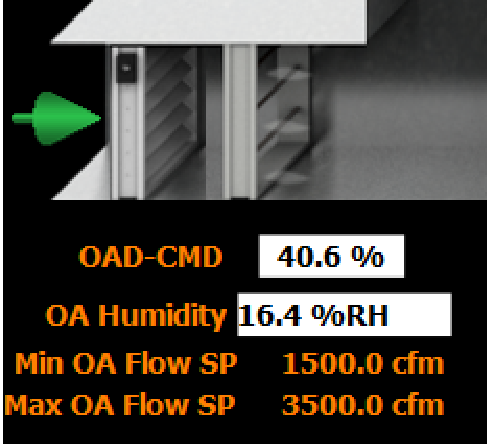

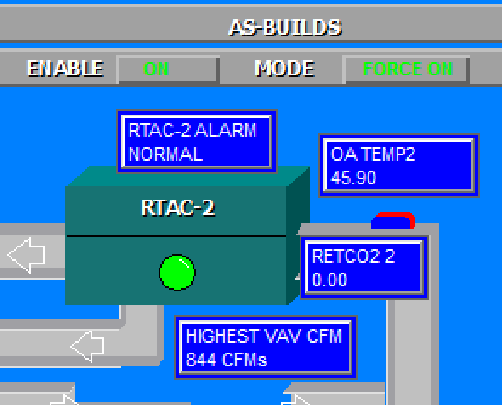

Minimum OAD Position Check

This measure determines whether the minimum OAD position is selected to capture the right balance between healthy indoor air quality (IAQ) during maximum load occupancy and energy efficiency.

This measure must be done when the air-side economizer is not in use, so better for it to be done in cold or hot weather when economizing is not enabled.

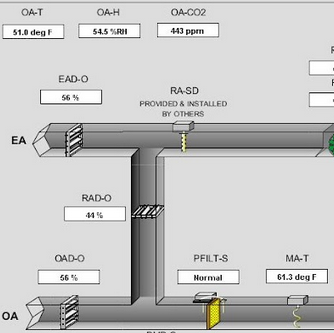

OA Control Using OAF

This measure can be used to determine whether outdoor air is properly managed. This measure assumes that neither Demand Control Ventilation (DCV) nor Energy / Heat Recovery Ventilation (ERV/HRV) are in use.

It is recommended that this measure is done in conjunction with Trend Chart 1: Fan Schedule to see if equipment are properly scheduled and following economizing controls.

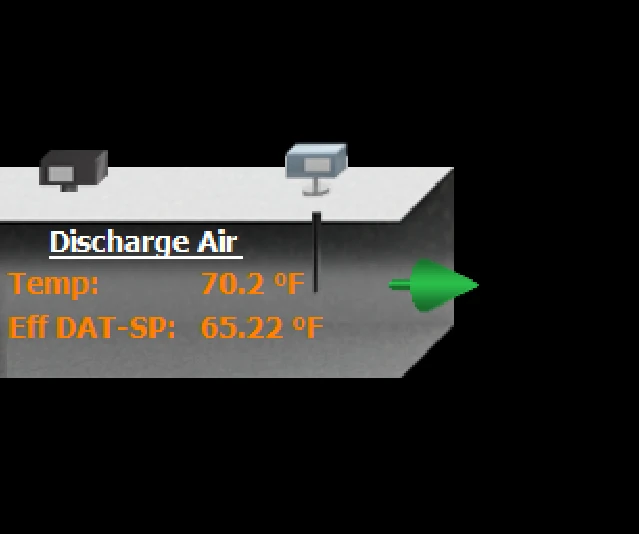

DAT Control

This measure monitors the DAT to determine whether a reset or change in DAT set point can be used to operate more efficiently, thereby preventing excessive DAT hunting, or an inability to reach the DAT setpoint. The DAT reset may be manual and/or be based on the RAT.

Download as PDF Related Kit Related Equipment

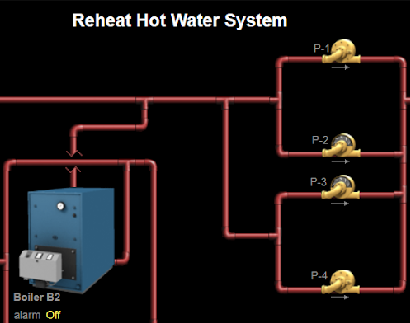

Reheats While Cooling

This measure is best used for a AHU/RTU with multiple zones with reheats. It monitors the MAT, SAT and VAV DAT to check that the SAT is not too low and that the reheats are all on.

Download as PDF Related Kit Related Equipment

Zone Temperature Setpoint

This measure monitors zone temperature and its setpoint to make sure that the setpoint is met. It is also important to note that if the temperature is meeting its setpoint, that it is not hunting; as well as making sure that it meets the setback, if there is one. The zone temperature should float towards the setback temperature during unoccupied times (when it is shoulder, heating, or cooling season).

Download as PDF Related Kit Related Equipment

OAT Verification

This measure validates the accuracy of your OAT sensors, by comparing them to logger and localized weather data.

Download as PDF Related Kit Related Equipment