Air System Leaks

Published: March 18, 2018

By: Felix Rodriguez, Equipment Specialist

Identifying and spotting air leaks

Identifying and spotting these air leaks can be tough. There are various rules of thumb on how to spot a leak: leaks occur within 30 feet of end use; listen for a hissing sound; watch for dust build-up and apply soap and water to check for bubbles.

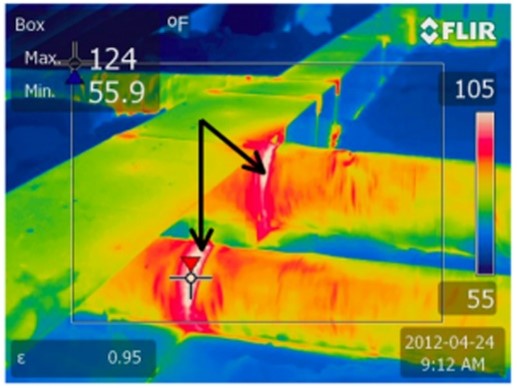

We have tools that can help you see and hear leaks. A thermal image camera is great for being able to see air leaks, especially around joints and connections of compressed air systems. Ultrasonic acoustic detectors are the best way to recognize high frequency hissing sounds that are associated with air leaks.

How to find a faulty steam trap

Use the CTRL UL101 Ultrasound Detector together with a solid probe attachment.

Step 1: Contact the steam trap

Step 2: Listen to the operation of the steam trap. Steam traps vary in type and operation, producing different sounds and indications of failures. Hear an audio clip of a steam trap in good condition below:

Step 3: Be proactive; every 3 years steam straps need to be replaced but if maintenance is provided within the time frame, loss of energy will be extremely less.

How to find a valve bypass leak

Use the CTRL UL101 Ultrasound Detector together with a solid probe attachment.

Step 1: Contact the valve housing.

Step 2: Listen when the valve is open; you will hear the rushing sound of gas or liquid flow. Adjust the sensitivity as necessary.

Step 3: Listen when the valve is closed. There should be no sound. If there is sound, there is an internal leak in the valve.