By CUNY BPL

The gymnasium had 60 metal halide fixtures that consumed up to 1000W each. The retrofit was to replace the metal halide fixtures with 380W LED fixtures. CUNY BPL was tasked with measuring the pre- and post-retrofit electricity consumption of the fixtures.

We needed to understand conditions in the library reading room where staff complained of cold temperatures. Unit heater problems were considered a likely cause along with a high infiltration rate.

Measurement Strategy

The lighting fixtures for the gymnasium were serviced by two lighting panelboards without automatic controls (dedicated panelboard without automatic controls). We decided to take direct measurements of AC current for both panelboards for several weeks.

This measurement strategy was chosen for two reasons:

- Because there were two panelboards it was easier to install the 4 channel analog loggers with Current Transducers since they took up less space inside the panelboard.

- We wanted to verify the hours of operation of the fixtures. By using the 4 channel analog logger we collected both the operating schedule of the fixtures and AC current of the panelboards.

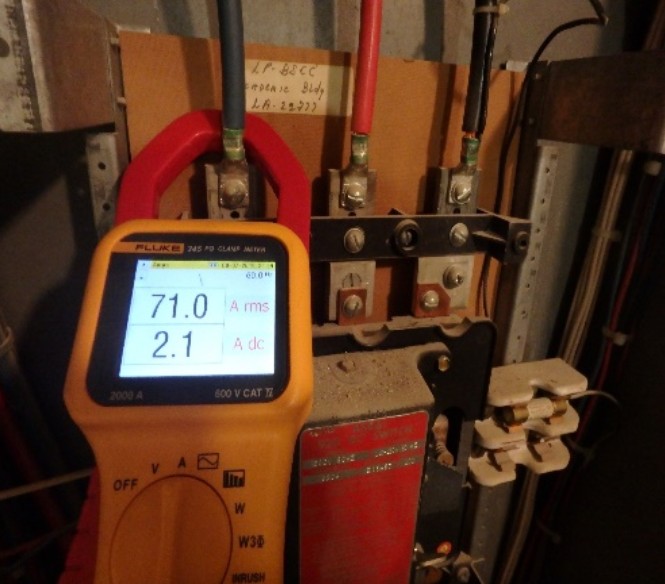

When using the 4 channel logger to measure AC current we also needed to measure the Voltage and power factor to calculate power. We did this by using a clamp meter to take spot measurements.

A one-time measurement of each incoming feed line was enough to give us the voltage and power factor.

Equipment

Supports up to four external sensors allowing you to measure temperature, current, voltage, air flow, pressure and more in one single logger.

Measures Power factor (PF), Reactive Power (VAR), Watt Hours (Wh), Kilowatt hours (kWh), AC Current, AC Voltage and more.

Used for metering current in switchboards, panelboards, and switchgear circuits. These are available in various amperage ratings.

Results

The 4 channel analog logger with CT sensors only measures AC current. To determine the energy consumption of the panelboard(s) we need the voltage for each line (assumed to be the same for a lighting panelboards) and the power factor. The clamp meter allows you to measure these parameters.

Lessons Learned

We did not use a light on/off data logger to determine the hours of operation of lighting fixtures because it is the least accurate method to determine the energy consumption of a space or facility. The reason is that the light on/off data logger is used for proxy measurements instead of direct measurements which are more accurate.

Since the panelboards were dedicated to lighting, easily accessible and we had plenty of 4-channel analog loggers and CT sensors, the better option was to take direct measurements, specifically AC current. You should only resort to using the light on/off data logger if you have facility constraints such as, inability to access panelboard or panelboard is mixed with other loads and you are unsure of what circuit breakers serve the light fixtures.

AGENCY

City University of New York

SITE

College Gymnasium