This time of year is ideal for inspecting your rotating machinery, including pumps, fans, compressors, and motors. Over time, the internal components of these machines can become unbalanced, misaligned, or loose, leading to potential issues. Using a Vibration meter & Tester helps detect excessive vibrations or misalignment, which can prevent motor failures and ensure optimal performance.

What is a vibration meter & tester?

The Fluke 805 Vibration Meter is a handheld tool designed to evaluate overall vibration levels and bearing conditions in mechanical equipment, providing a severity-scaled assessment of bearing health.

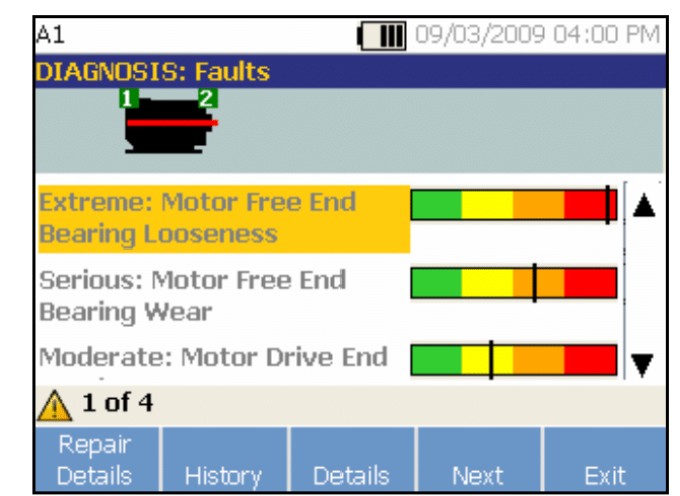

The Fluke 810 Vibration Tester takes diagnostics a step further by identifying machine faults during initial measurements, even without prior baseline data. It also provides repair recommendations, helping to make informed maintenance decisions.

Benefits of Using Vibration Meter & Tester

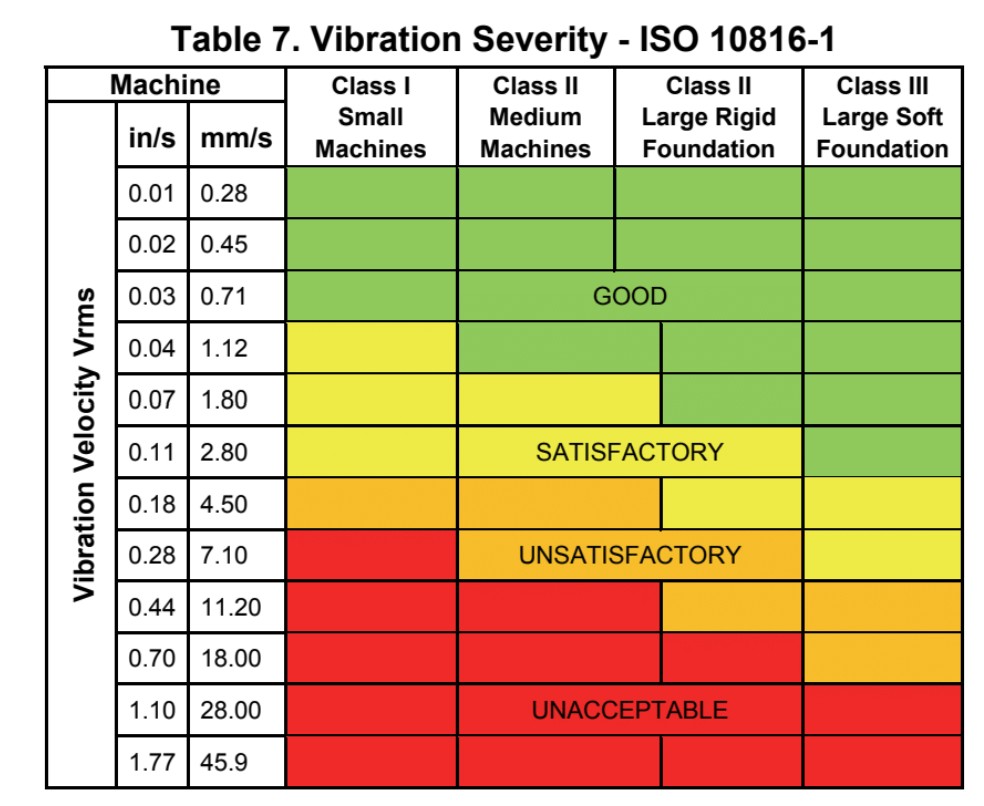

- Vibration Severity Scale: The meter utilizes the ISO 10816 standard to assess overall vibration severity, offering a reliable benchmark for evaluation. Table 7 below includes reference values from this standard, allowing you to compare measured vibration levels and determine the appropriate actions based on severity.

Fluke 805 Vibration Meter Manual

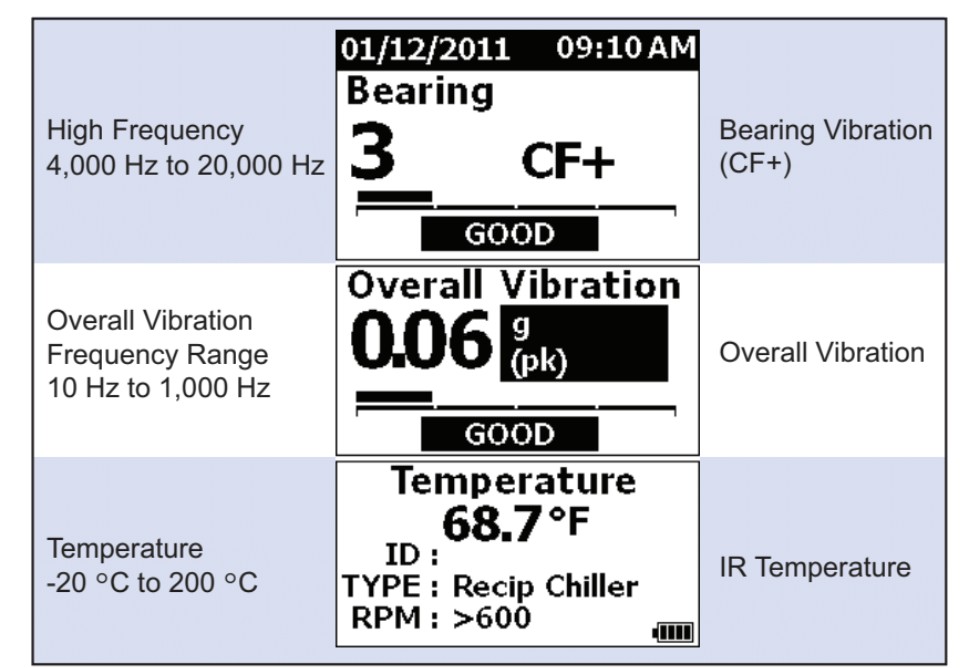

- Crest Factor + High Frequency Measurements: The meter evaluates both bearing health and overall machine vibration through three key measurements: bearing vibration, overall vibration, and temperature. The crest factor—the ratio of peak value to RMS value in a time-domain vibration signal—is a critical metric used by vibration analysts to detect bearing faults. As a bearing starts to degrade, the peak value increases, raising the crest factor. However, as damage progresses and the RMS value rises, the crest factor begins to decline. A low crest factor could indicate either a healthy bearing or one in severe failure, making accurate interpretation essential.

- Predictive Maintenance: Early detection of misalignment, imbalance, or loose components in rotating machinery helps prevent failures and extends equipment lifespan.

Fluke 805 Vibration Meter Manual

Fluke 810 Vibration Tester Manual

You can check out our equipment library to find vibration meter & tester suitable for your application by using the various filters and search functionality. For more guidance on equipment suitable depending on the application, see our measurement guides.